Product Description:

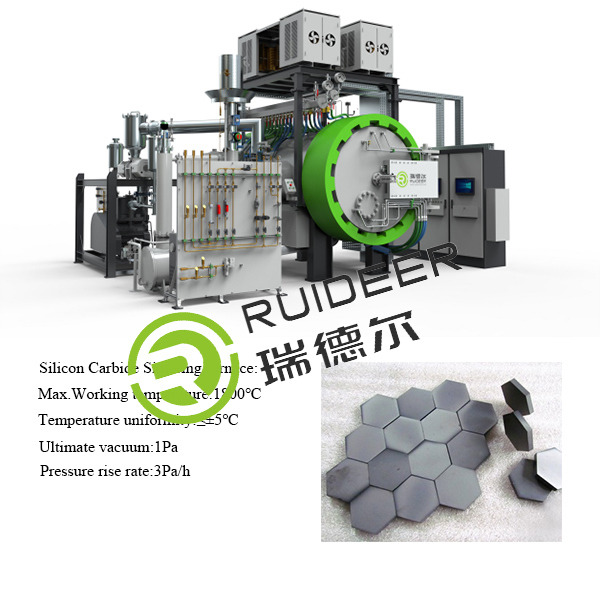

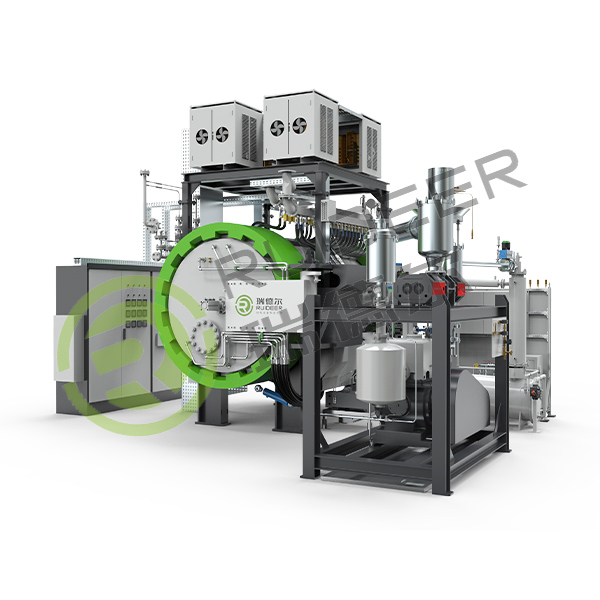

The Ceramic Sintering Furnace is an intelligent sintering furnace designed for high-performance ceramic sintering applications. With its advanced features and capabilities, this furnace offers precise control over the sintering process to achieve superior results.

One of the key highlights of this furnace is its ability to achieve a sintering purity of ≥ 98%. This is made possible through the use of 10kg of Paraffin Refined Wax and Ar negative pressure dewaxing technology. With these features, the furnace ensures that the final sintered product meets the highest quality standards, with three averages at most.

When it comes to cooling, the furnace is equipped to efficiently cool down from a sintering temperature of 1450 ℃ to 100 ℃. The cooling time for an empty furnace is less than or equal to 2/4/7 hours, ensuring quick cooling cycles for improved efficiency.

The Ceramic Sintering Furnace is an integrated type furnace, offering a seamless and user-friendly operation. It is designed to meet the demands of modern ceramic sintering processes, providing advanced features and functionalities for enhanced performance.

With a maximum temperature of 2400℃, this furnace is capable of handling a wide range of sintering applications with precision and accuracy. Whether you are sintering ceramics for research purposes or industrial production, this furnace delivers consistent and reliable results.

Operating at a power supply of 380V, the furnace is energy-efficient and cost-effective, making it an ideal choice for various sintering operations. Its intelligent design ensures optimal performance while maintaining a high level of safety and reliability.

In conclusion, the Ceramic Sintering Furnace is a versatile and advanced sintering solution that combines the benefits of an intelligent sintering furnace, vacuum sintering furnace, and protective gas sintering furnace. With its superior sintering purity, efficient cooling system, integrated design, high temperature capabilities, and energy-efficient operation, this furnace is a valuable asset for any ceramic sintering application.

Features:

- Product Name: Ceramic Sintering Furnace

- Advantage: Long Service Life

- Color: White, Gray, Black, Blue, Green

- Power: 380V

- Type: Integrated

- Temperature control independently: ≤ ±5 ℃ (using Ferro Brand MTH Temperature Measuring), Provided By The User. Under Vacuum Sintering Conditions, Follow The Processes Listed In The Item 10 Final Acceptance At The Buyer’s Site. The Temperature Measuring Ring Will Be Placed On The Graphite Plate For Testing At 1350-1550°C.

Technical Parameters:

| Leakage rate |

≤3Pa/h (Measuring The Limit Vacuum After Drying The Furnace, Stop The Operation Of The Pump Group And Start The Test. Average Within 3 Hours In Empty Furnace, Clean And Cold State) |

| Atmosphere Control |

Gas Mixing System |

| Max.loading weight |

50/ 100/ 150/ 300/ 500/ 1200/ 1500KGS |

| Working Pressure |

10/20/30/60/100/200 Bar |

| Pumping speed |

The Vacuum Degree Can Reach 5 Pa Within 30 Min After The Pump Is Started, And The Limit Vacuum Value Can Reach 1Pa After Pumping For 60 Min After Reaching 5 Pa (After Drying The Furnace, Under The Empty Furnace, Clean And Cold State) |

| Heating Method |

≥ 98%(10kg Paraffin Refined Wax , Ar Negative Pressure Dewaxing, Three Averages At Most) |

| Max. temperature |

2400℃ |

| Power |

380V |

Applications:

RUIDEER Ceramic Sintering Furnace is a cutting-edge product designed for various application occasions and scenarios due to its advanced features and high performance. The furnace, available in models 224, 4412, 5512, and 5518, is manufactured in China and offers exceptional capabilities for high-temperature sintering processes.

One of the key attributes of this furnace is its maximum temperature of 2400℃, making it ideal for applications that require extreme heat conditions. The 3-zone temperature control independently allows for precise and customizable temperature settings, ensuring optimal sintering results.

With a heating power of approximately 320KVA, the RUIDEER furnace requires a cable with a cross-section area of at least 185mm2, providing the necessary power for efficient operation. The vacuum sintering capabilities of the furnace are impressive, with the vacuum degree reaching 5 Pa within 30 minutes of starting the pump and a limit vacuum value of 1Pa after 60 minutes of pumping.

The high accuracy temperature control of the furnace, with a tolerance of ±5 ℃ using Ferro Brand MTH Temperature Measuring, ensures precise and consistent sintering conditions. Users are required to follow specific processes for temperature control under vacuum sintering conditions, as outlined in the product documentation.

The RUIDEER Ceramic Sintering Furnace is well-suited for a range of scenarios, including vacuum sintering processes, structural ceramic sintering, and high-accuracy temperature control sintering applications. Whether in research laboratories, industrial settings, or manufacturing facilities, this furnace delivers reliable performance and exceptional results.

Customization:

Support and Services:

The Ceramic Sintering Furnace product comes with comprehensive Product Technical Support and Services to ensure optimal performance and customer satisfaction. Our support includes:

- Installation assistance and guidance

- Training sessions for operators and maintenance staff

- Troubleshooting and diagnostic support

- Regular maintenance and calibration services

- Software updates and technical documentation

Our team of experts is dedicated to providing timely assistance and expertise to address any technical issues and maximize the efficiency of the Ceramic Sintering Furnace.

Packing and Shipping:

Product Packaging:

The Ceramic Sintering Furnace is carefully packaged in a sturdy cardboard box to ensure safe transportation. Each component of the furnace is securely wrapped in bubble wrap to prevent any damage during shipping.

Shipping Information:

We offer worldwide shipping for the Ceramic Sintering Furnace. Orders are processed within 1-2 business days, and shipping times may vary depending on the destination. Customers will receive a tracking number to monitor the status of their shipment.

FAQ:

Q: What is the brand name of this Ceramic Sintering Furnace?

A: The brand name is RUIDEER.

Q: What are the available model numbers for this Ceramic Sintering Furnace?

A: The available model numbers are 224, 4412, 5512, and 5518.

Q: Where is this Ceramic Sintering Furnace manufactured?

A: This Ceramic Sintering Furnace is manufactured in China.

Q: What is the maximum temperature that this Ceramic Sintering Furnace can reach?

A: The maximum temperature varies depending on the model, but typically ranges from 1200°C to 1800°C.

Q: Does this Ceramic Sintering Furnace come with a warranty?

A: Warranty information may vary, please refer to the product documentation for details.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!